NOTES ON THE A5 Design:

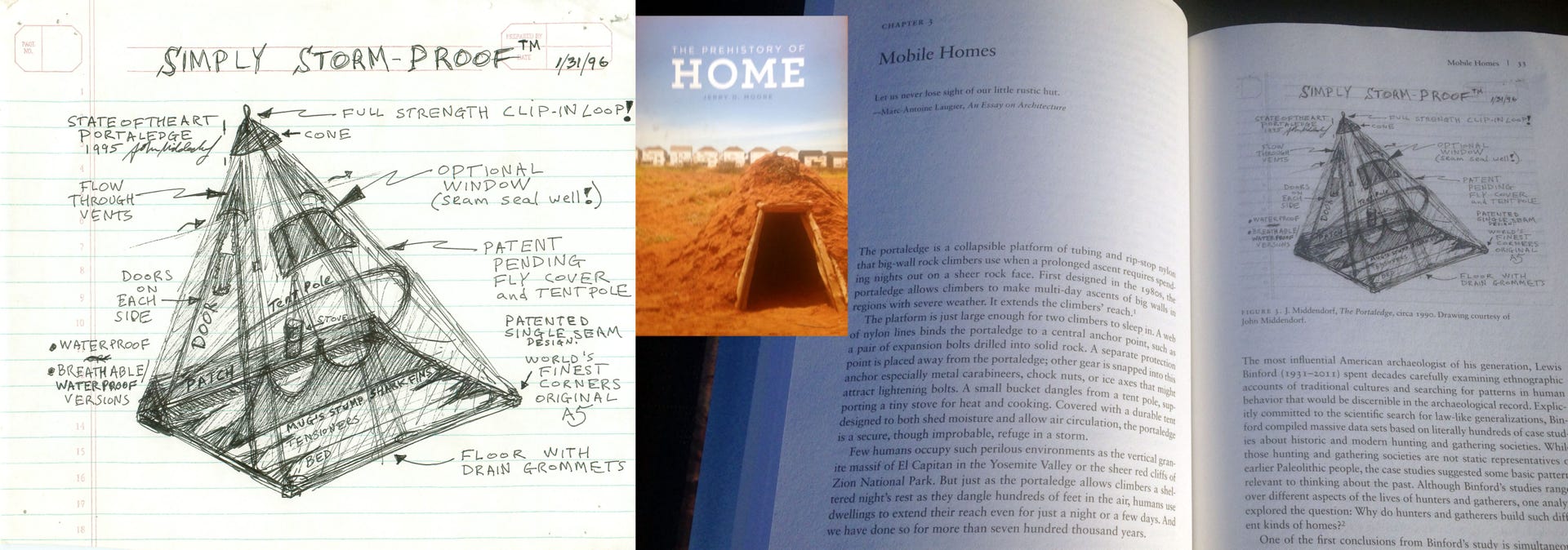

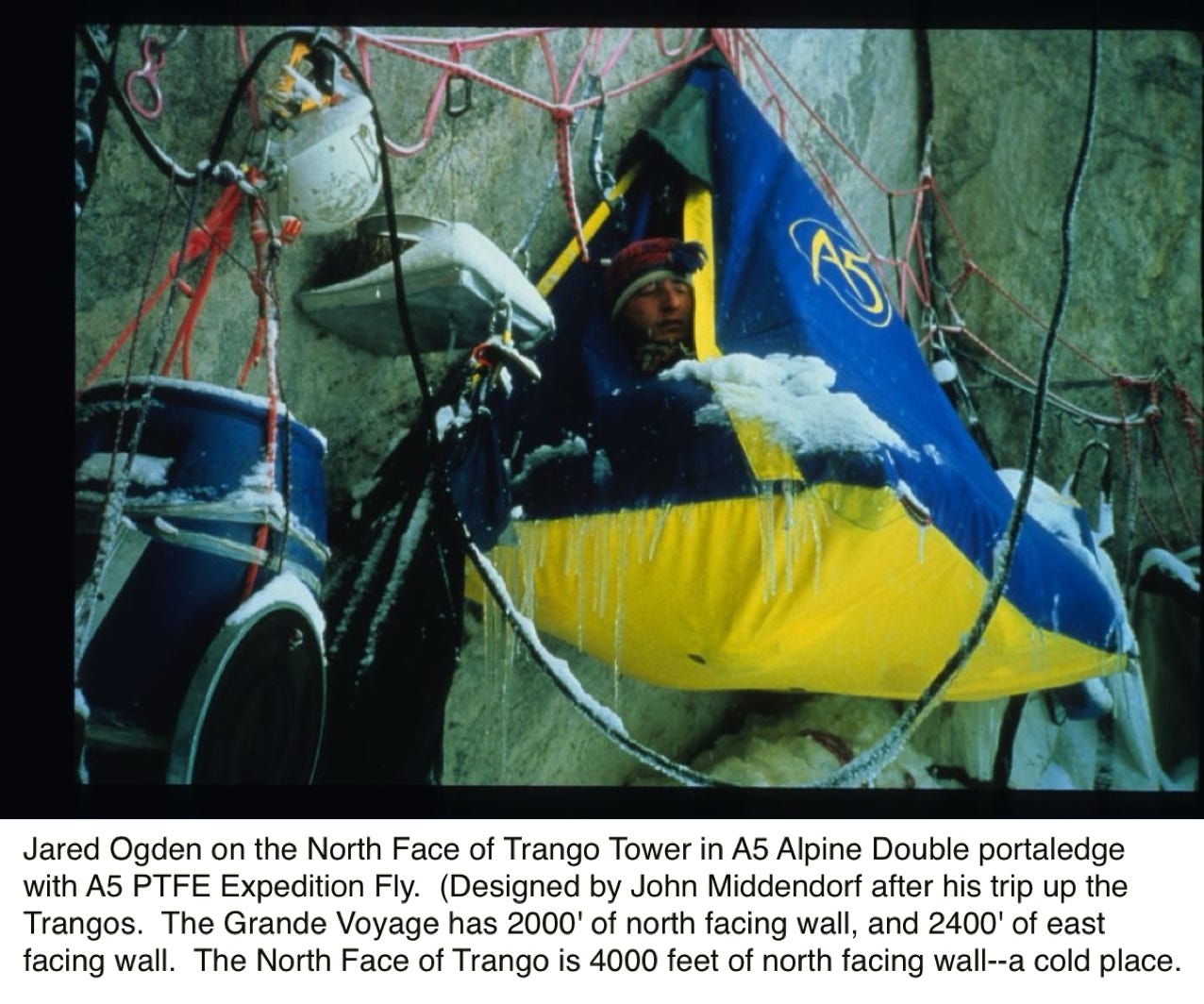

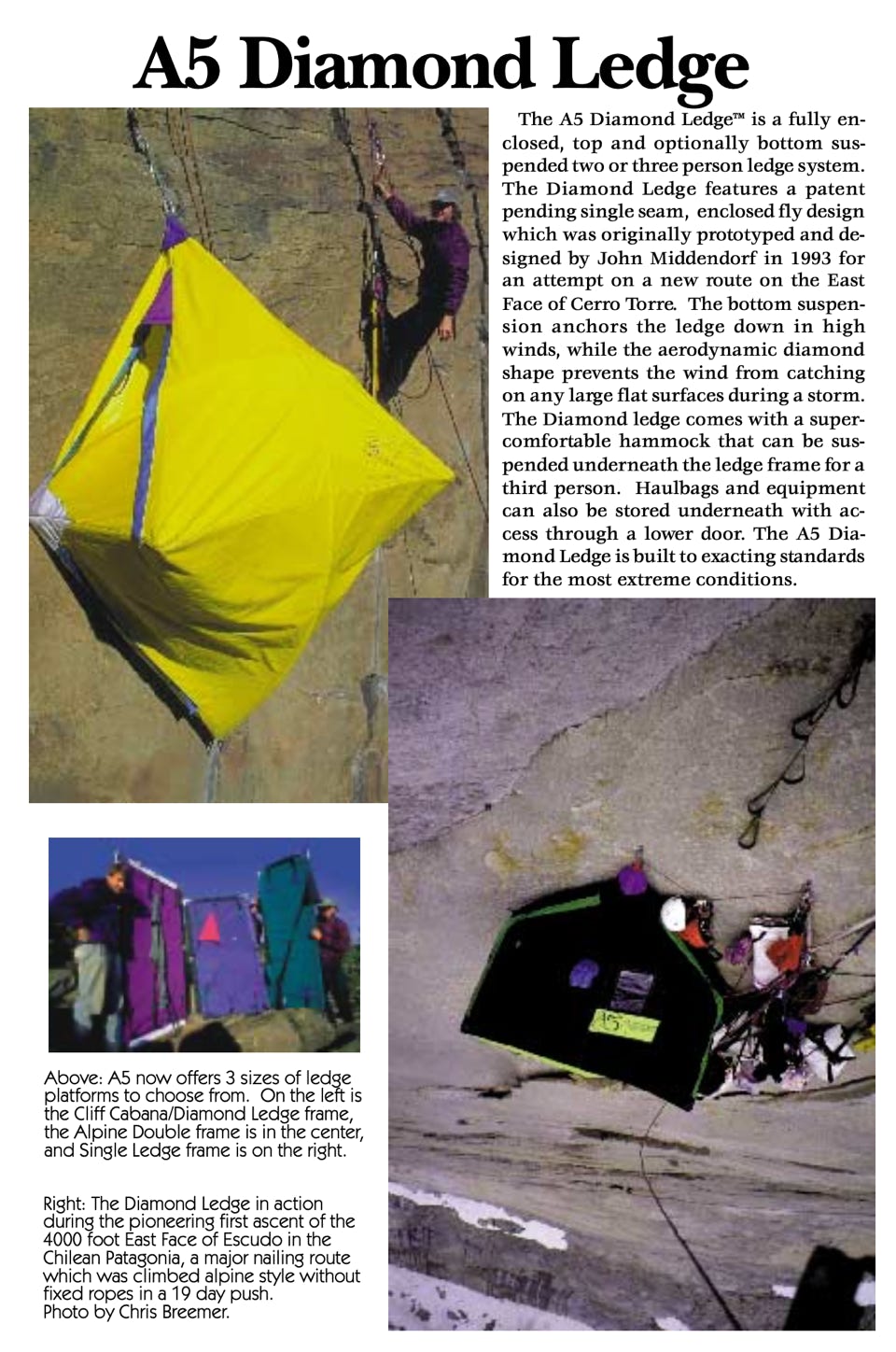

The A5 Design was the de-facto state-of-the-art portaledge design from 1987-2017, copied by the major manufacturers, and was the portaledge of choice on pretty much every cutting edge big wall ascent for all those years. It is worth reviewing portaledge design history, as often history repeats, sometimes with less-optimal examples. The A5 "block corner" portaledge I originally designed in 1987 was the first truly stormproof portaledge with strong frame and burly storm cover, and was key to a new standard of big wall alpine climbs.

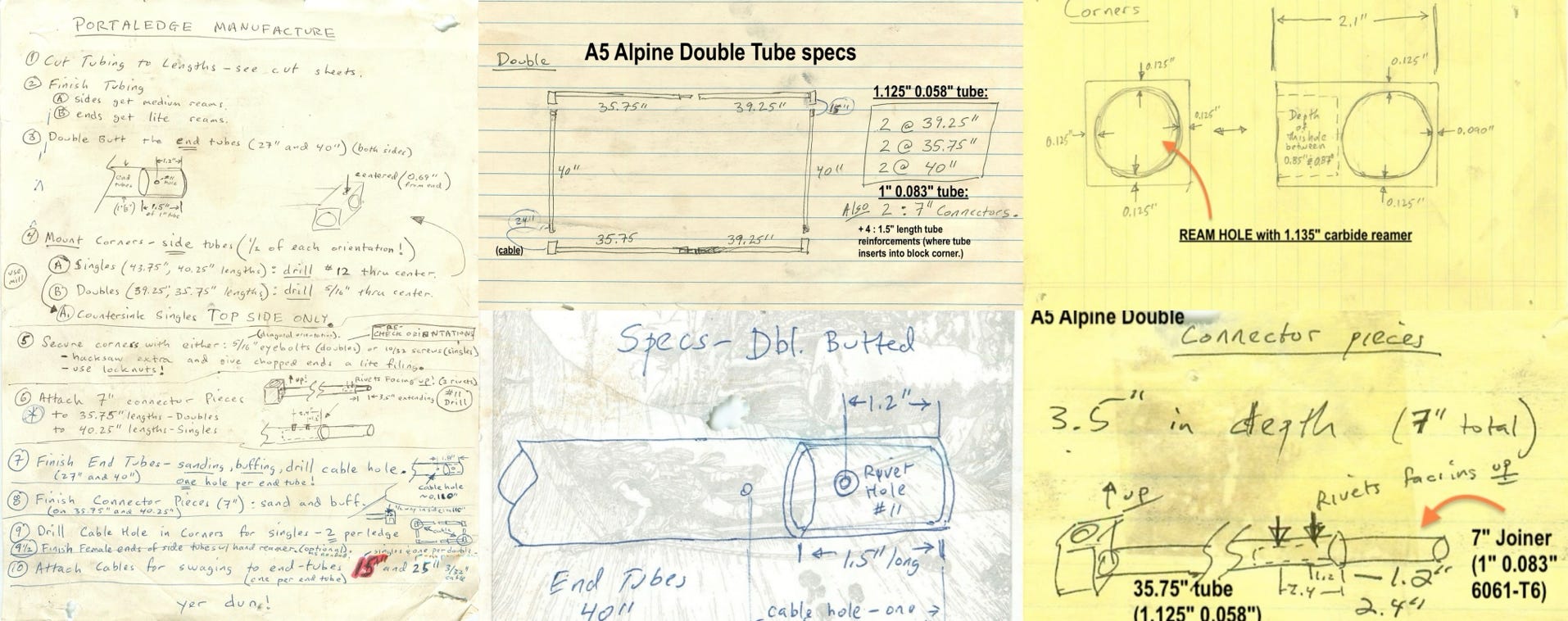

To make your own A5 design, the hardest part is finding an affordable source of block corners, as the tolerances on the block corners need to be precise for the frame to function well. Info on the A5 design was originally shared on bigwalls.net BigWallForum in the early 2000's, and spawned a lot of online DIY tutorials, like this one for the fly and this one for the frame (but do not make open block corners!). I have also helped dozens of home builders and manufacturers to design and make their own portaledges.

The A5 "block corner" design is still a viable design if machined corners are easy to obtain, though it has disadvantages (i.e, less rigidity of frame compared to hybrid-diameter, curved corner frames).

The A5 Design has now been superseded by the D4 design.