Welcome to Big Wall Gear's open source D4 Portaledge Design.

How to create your own curved tube portaledge frames, the lightest, most compact, and strongest ledge system, as well as stormproof D4 innovations such as the single seam corner-pocket zipped fly that make for the most secure and versatile storm system ever. Information presented "as is" from my notes and notebooks--feel free to contact me for any particular D4 open source design you are interested in, and I will try to help. WARNING: Build and use at your own risk. Always stay tied in short to the main anchor when testing or using any single-point hanging portaledge!

D4 DESIGN INFO (lots of preliminary ideas as well as key design info):

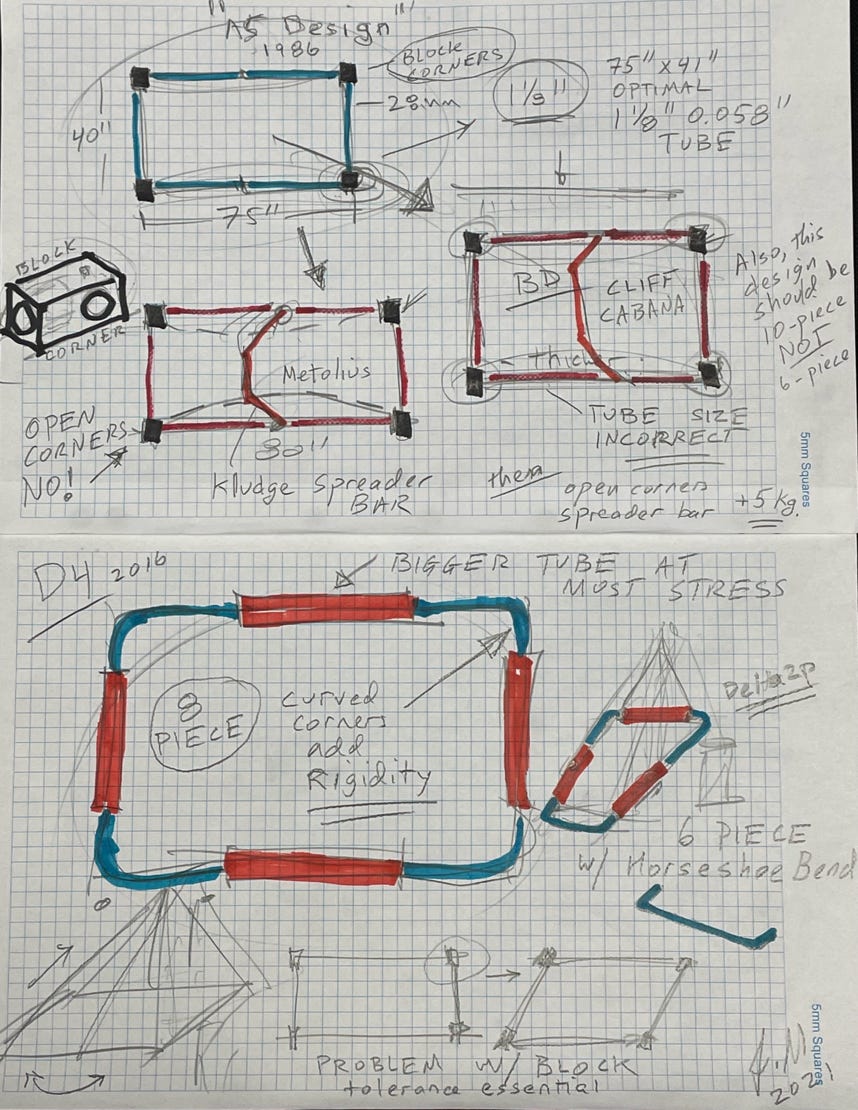

- D4 Delta Design Notebook (Delta1p, Delta2p, Delta3p) 2020

- Open Source Delta1P--a six-piece "coffin shaped" D4 design

- D4 Full-Size Portaledge Journal (8-piece design) 2017

- D4 Trapezium Journal (frame, bed, and fly pattern) 2018

- D4 Octapod Journal (double bend designs) 2019

--------------------------------------------------------

A5 Portaledge info:

The A5 Adventures portaledge design (1987-2017)

FEA comparison of A5 block corner vs D4 design (2021)

-->SIMPLEST DIY PORTALEDGE (Activist BBF)

Optimal PORTALEDGE DESIGN is the D4 DESIGN (supersedes the A5 DESIGN)

ALL MATERIAL PRESENTED AS CREATIVE COMMONS OPEN SOURCE WITH ATTRIBUTION.

ASPECTS OF THE D4 DESIGN (partial list):

CURVED CORNER TUBES

HYBRID DIAMETER FRAME

D4 BULLET JOINERS

D4 FLY SYSTEM.

D4 DELTA FRAME AND OTHER D4 FRAME DESIGNS.

-->ATTRIBUTION MEANS REFERENCE TO THE D4 DESIGN

Principles of the D4 Design self-assembling portaledge design:

by John Middendorf A5/D4 Portaledge Designer

1. Frame needs to be rigid (I.e. no hinges or open corners--any play results in a wobbly platform).

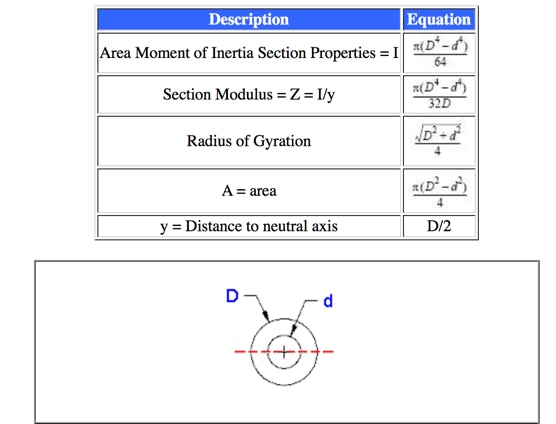

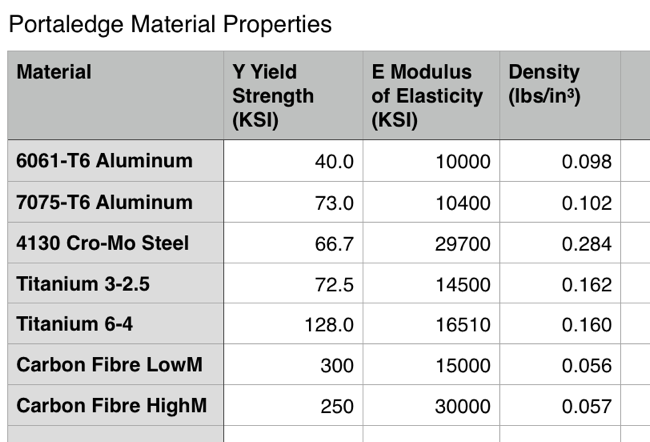

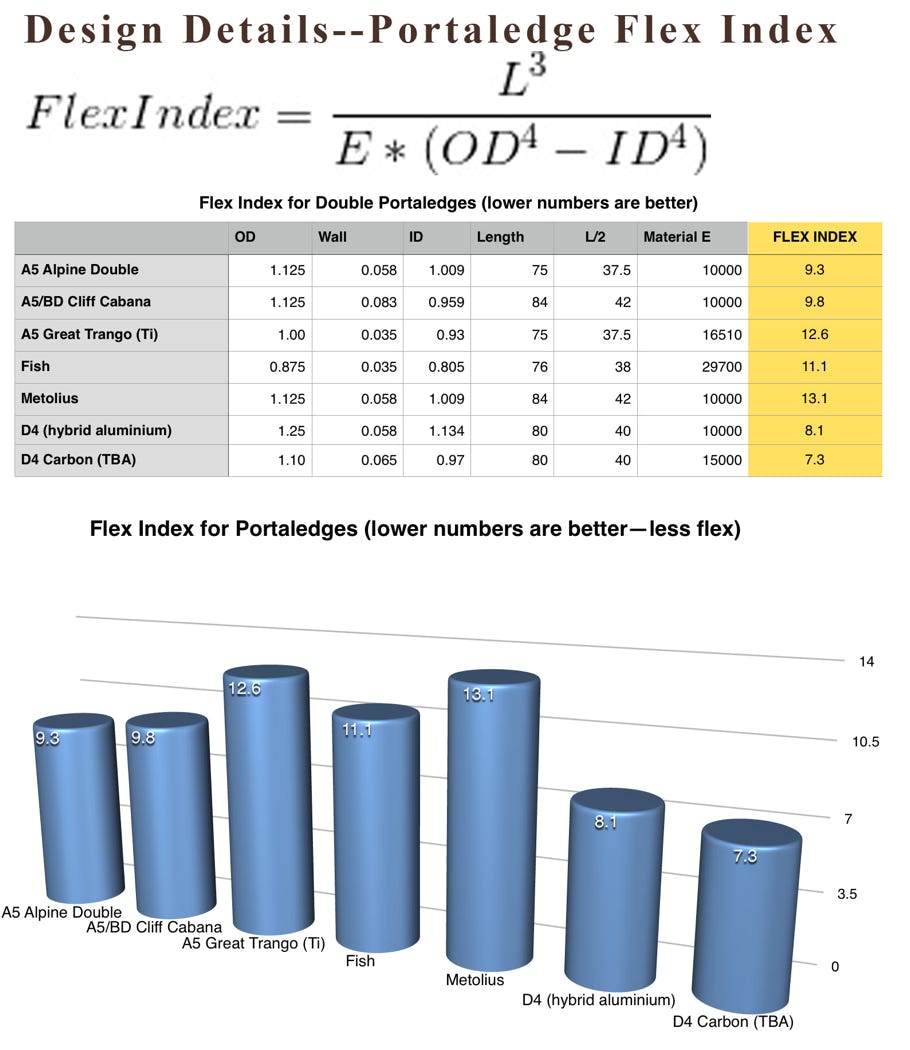

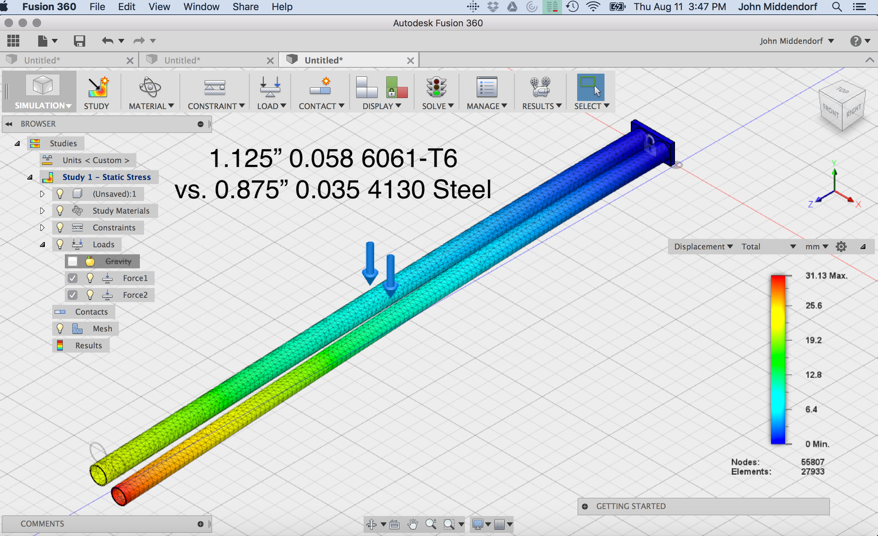

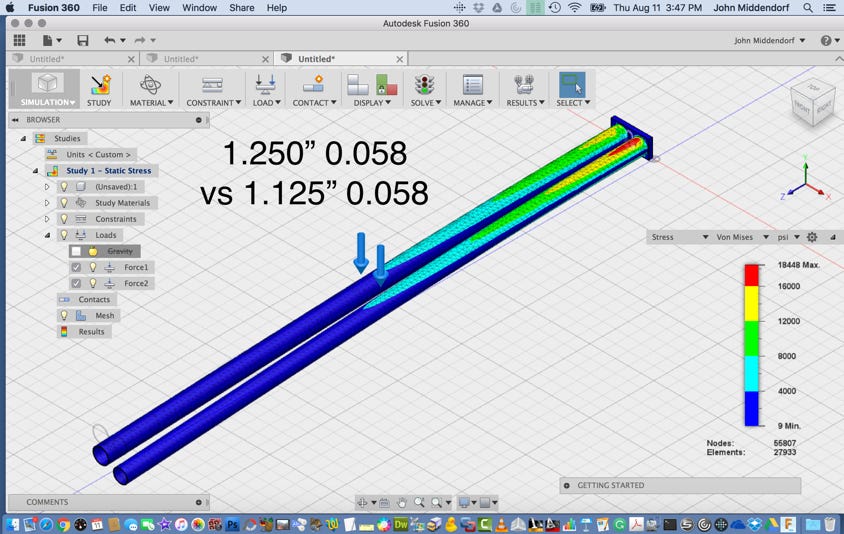

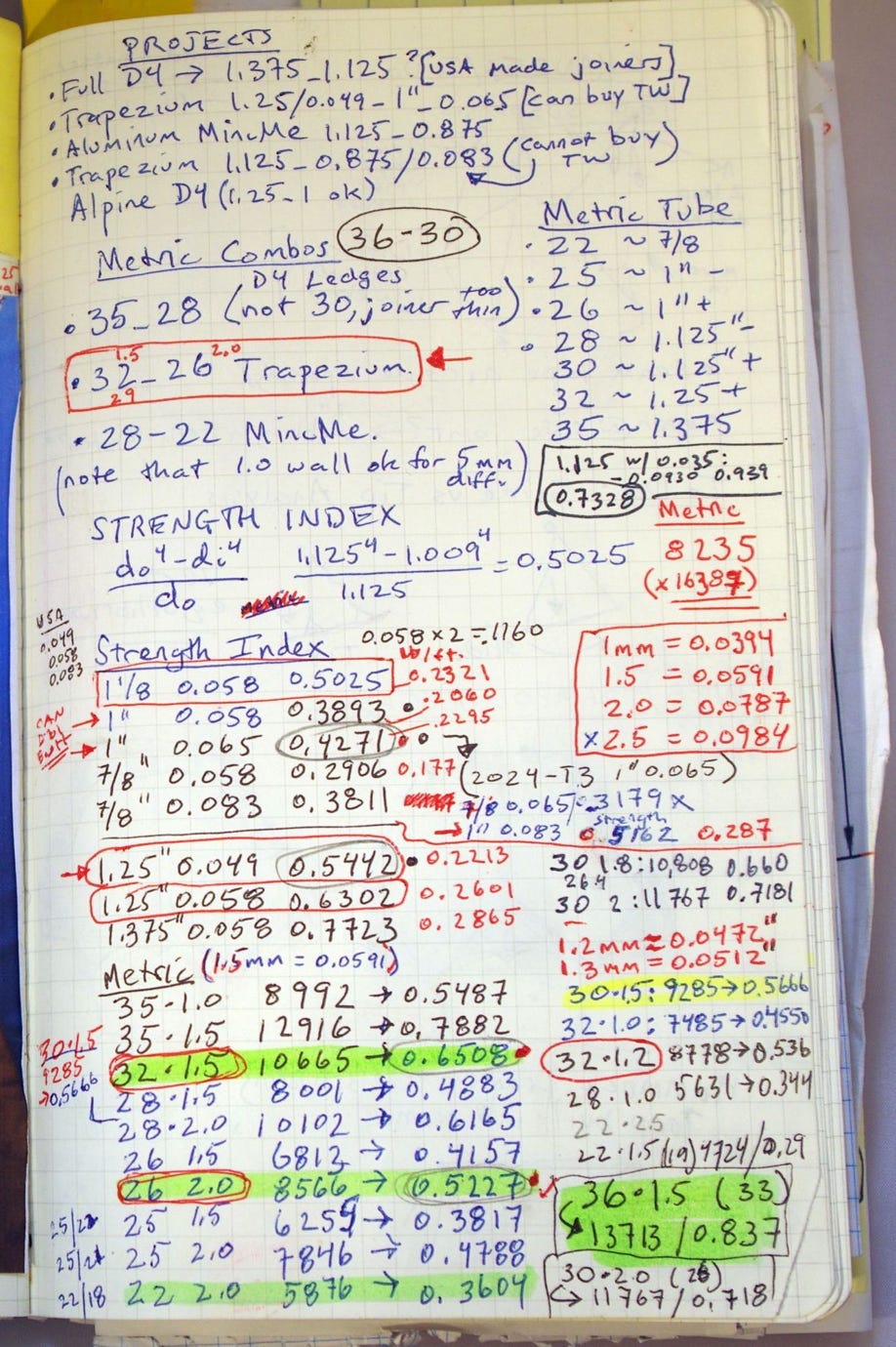

2. For optimal strength-to-weight ratio, use multiple size tubes (outside diameter) in your design--the hybrid-diameter frame--use larger diameter in areas of greater stress to create the most rigid frame. Understand strength and deflection formulas to determine tube sizing for a particular frame size and shape.

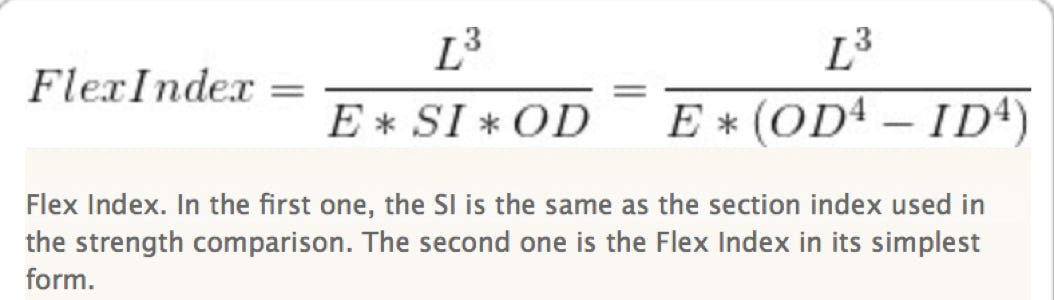

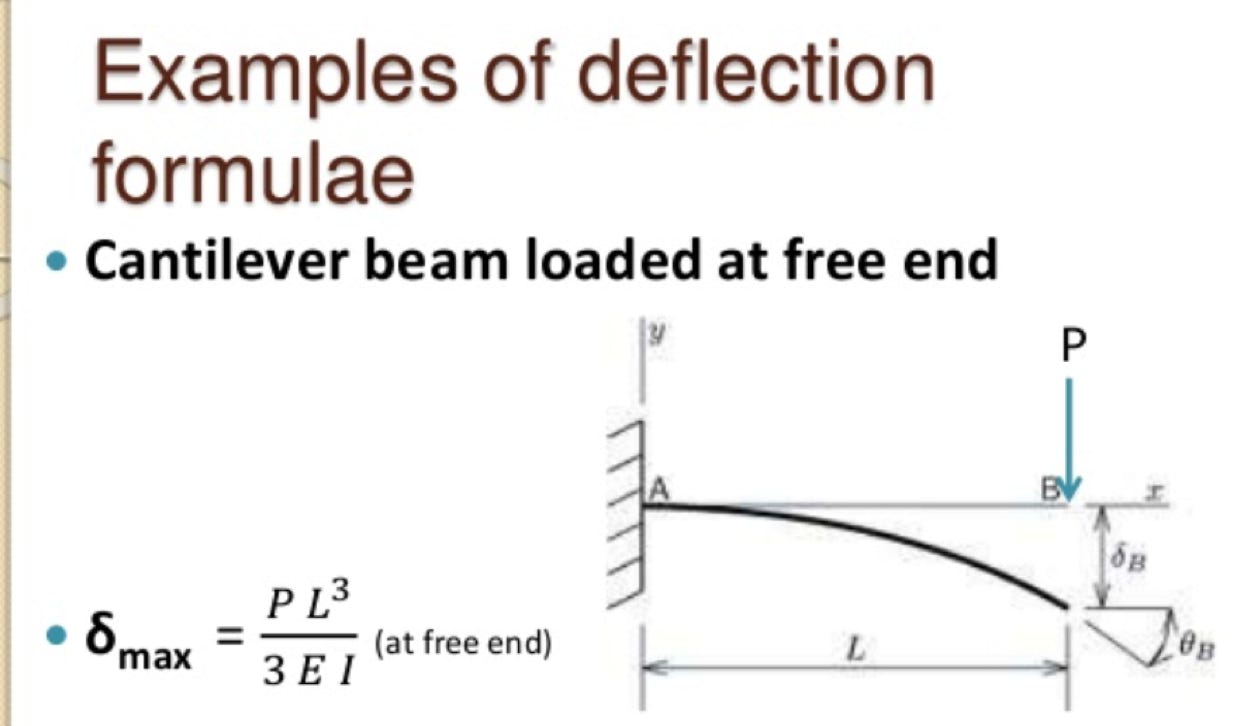

3. Consider deflection as a primary design criteria--based on your choice of material (modulus), strength will follow. A rigid, non-flexing frame makes for the strongest, most stable platform.

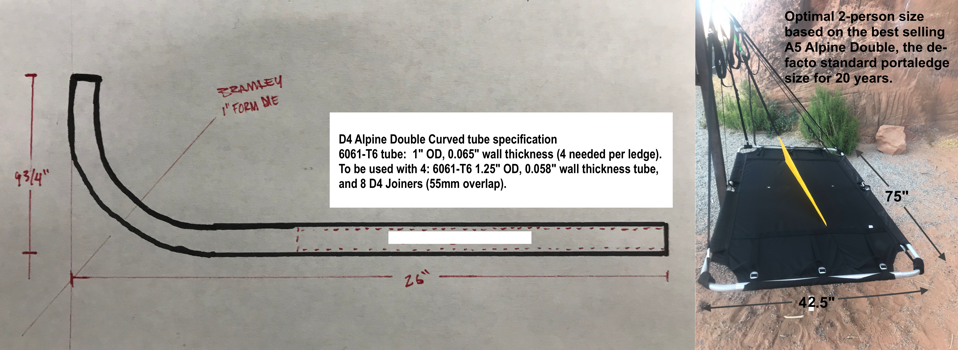

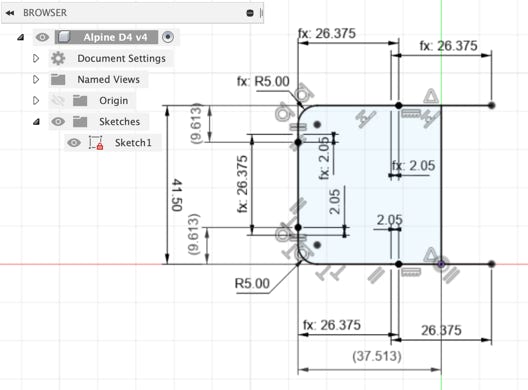

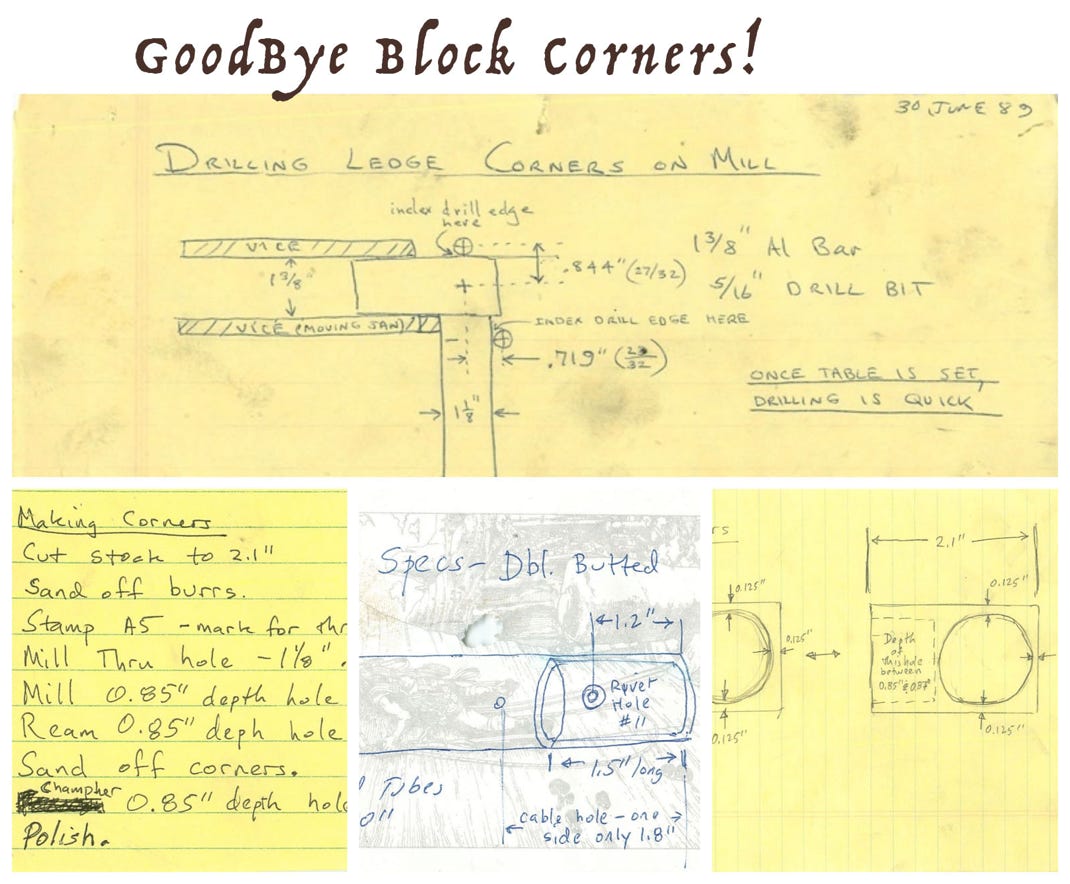

4. Curved tubular corners offer more frame rigidity than block corners, as well as offering lighter and more versatile designs and optimal shapes. As a design gets more rounded, the overall hoop strength increases.

5. The folding configuration is the other main design criteria. Design for compact folding (all tubes same length), and for unfolding patterns. A simple rectangular shape is simplest, but the "cantilevered" delta shape is a more stable platform.

6. The D4 overlapping-tube "Bullet Joiners" (patent applied for, now open source) have been proven excellent for ease-of-setup, strength/weight, and simplicity (continuous shock-corded frame) are the ideal joiner system for a collapsable folding frame.

7. The fly cover can be designed with with minimal seams, and with zipper openings and the D4 "corner-pocket" system (drawcord-free) and making the most windproof ledge/fly system, while being versatile by allowing full airing of ledge without sacrificing security when zipped.

8. Frame suspended ledges feel more solid than fabric (fin) suspended ledges. The reason is the fabric shifts in its sleeve for fabric supported systems, and the frame flexes accordingly as the stresses shift.

9. Frames will be less prone to "taco" if you include a double bend tube one or both ends of your design.

10. A5 innovations also apply and many details brought forward with the D4 design.

THE MOST IMPORTANT ASPECT OF BUILDING YOUR OWN GEAR--> TEST!

3 basic rules for designing and making your own portaledge:

1. DESIGN and BUILD. (First step: determine tube diameter, wall thickness, and material).

2. TEST (overload the ledge in a variety of configurations (overhanging, flat wall, on a tree), until something bends or breaks. Consider carefully failure mode.

3. REBUILD. Refurbish your tested prototype by reinforcing all points of weakness exposed in your test. The ledge should be able to support twice it's intended capacity at a minimum (All A5/D4 original designs robustly tested with up to 8 people bouncing--on a remote wall, life in a ledge can be a rodeo).

TUBING

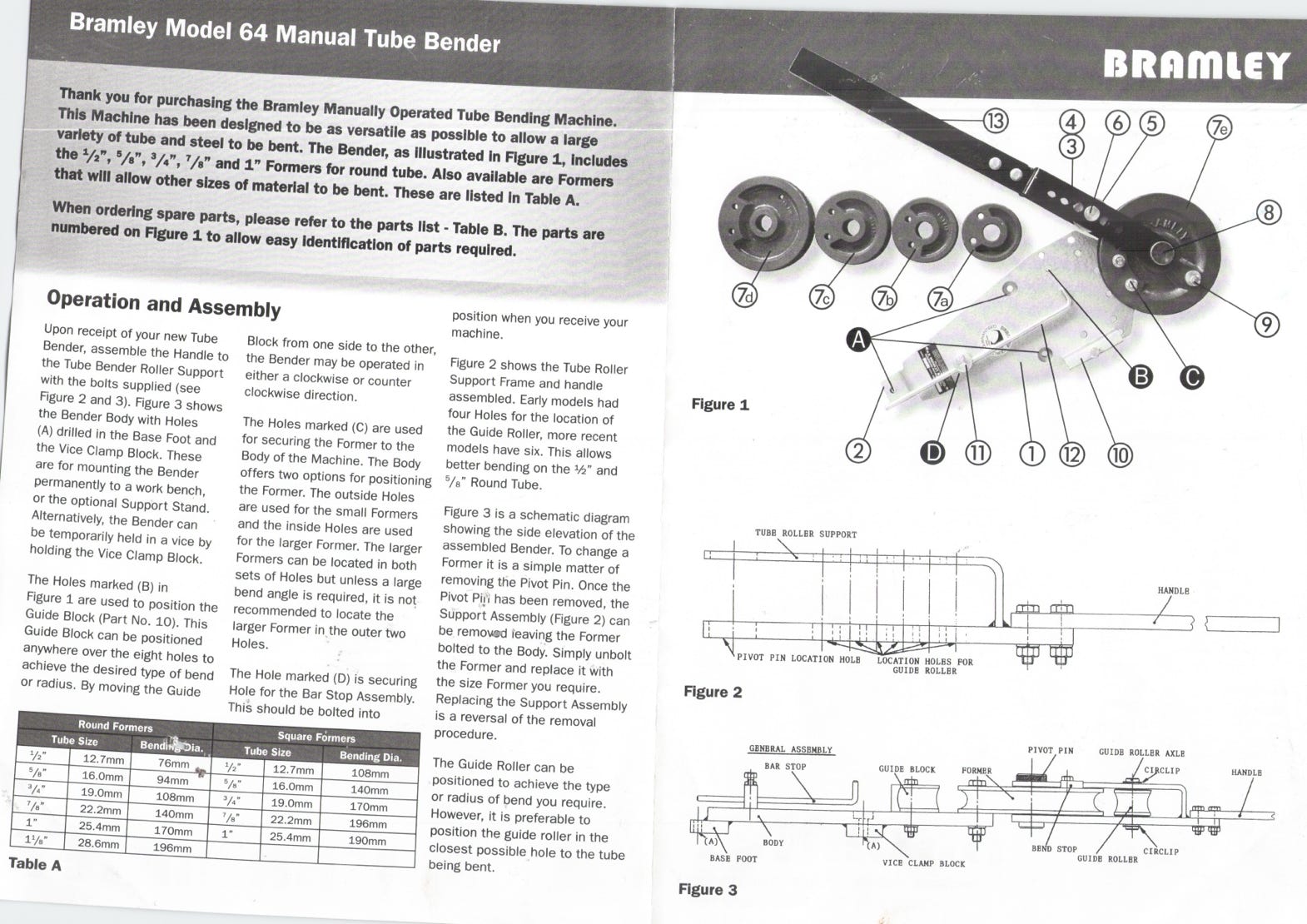

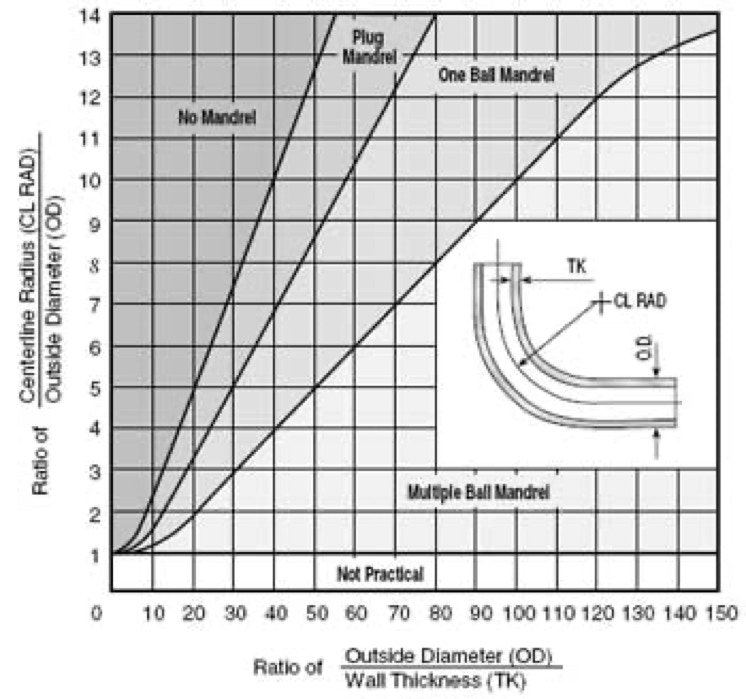

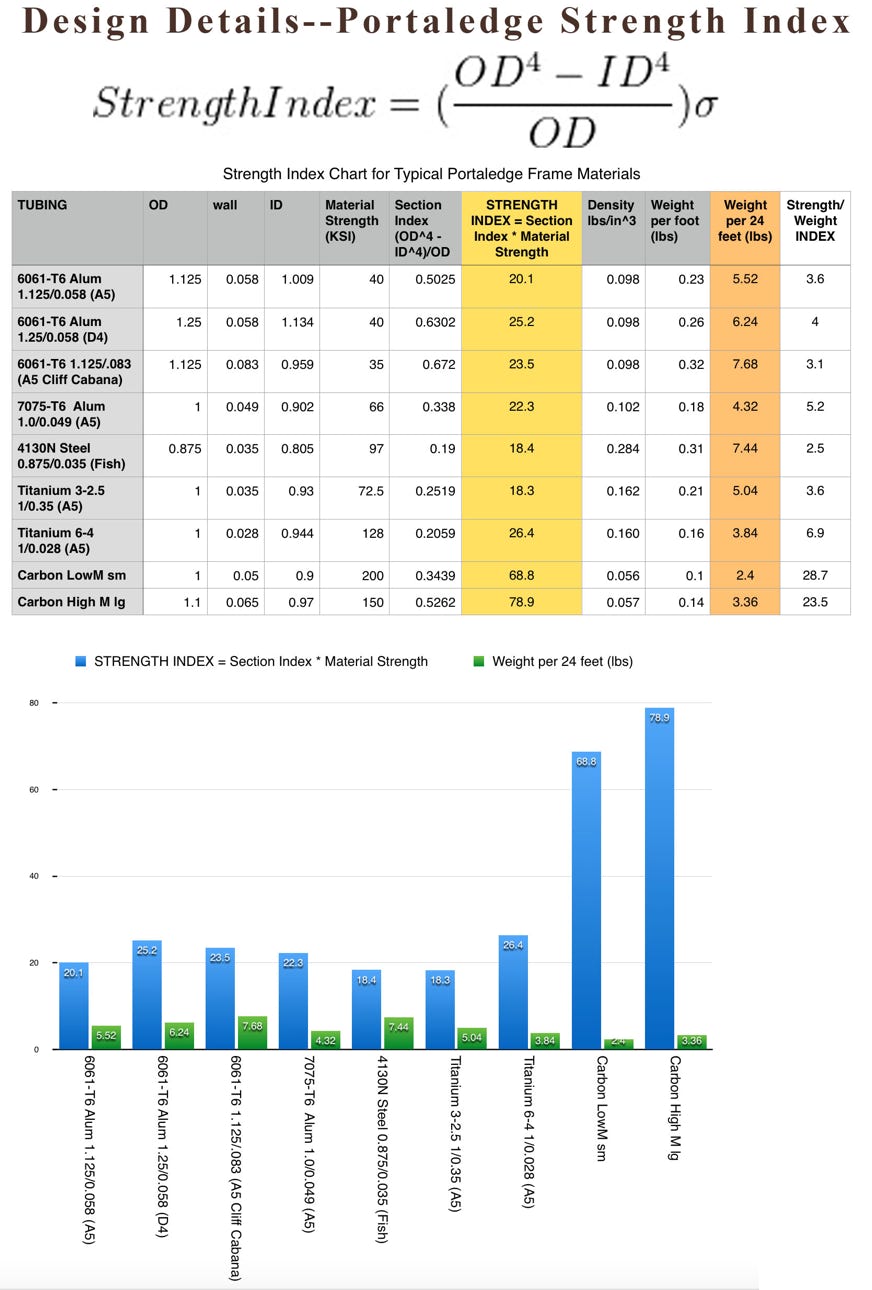

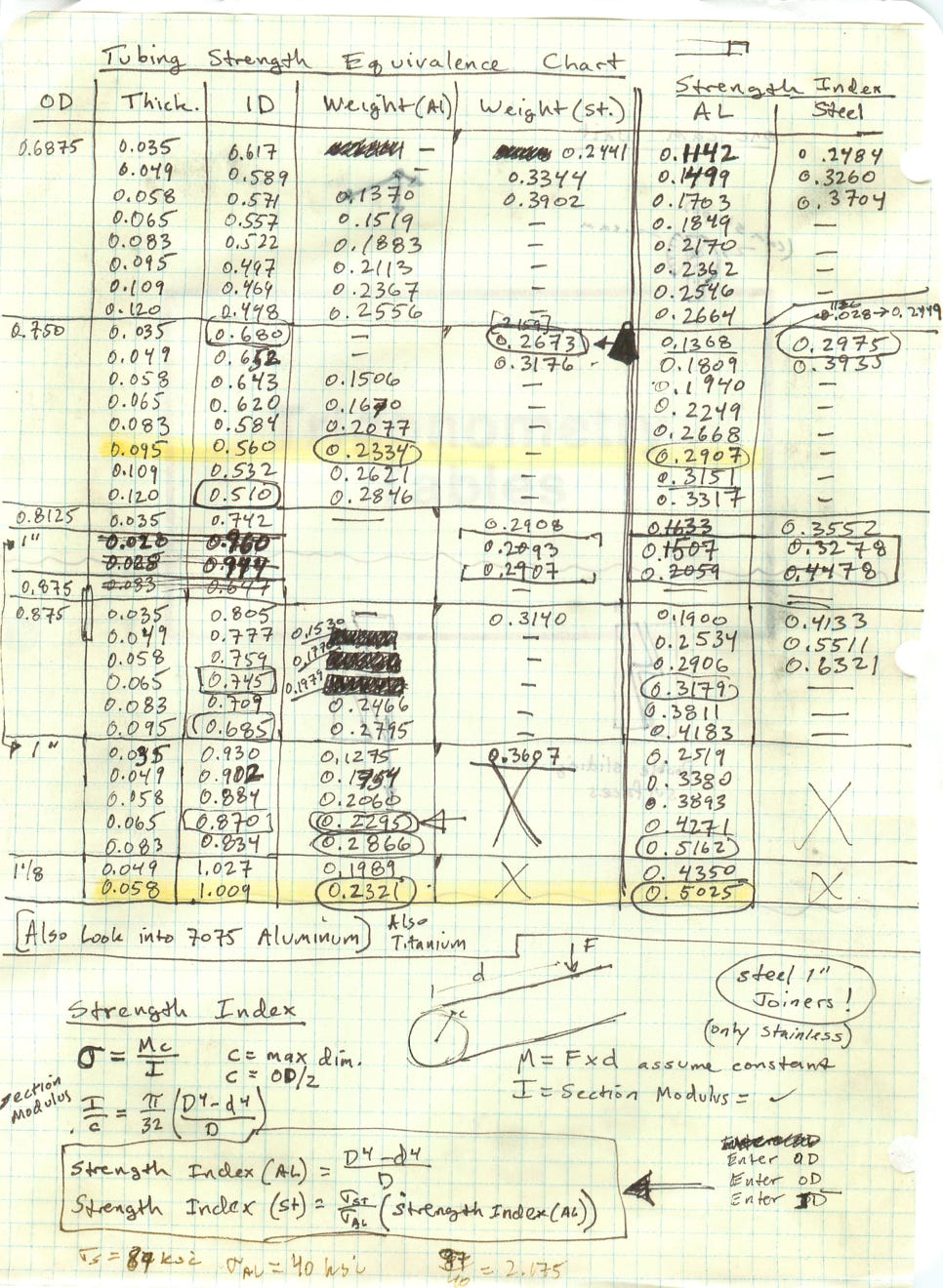

It all starts with the frame. See this document for a primer on frame strength, deflection, and weight: GoodByeSpreaderBars.pdf. (summary images below)

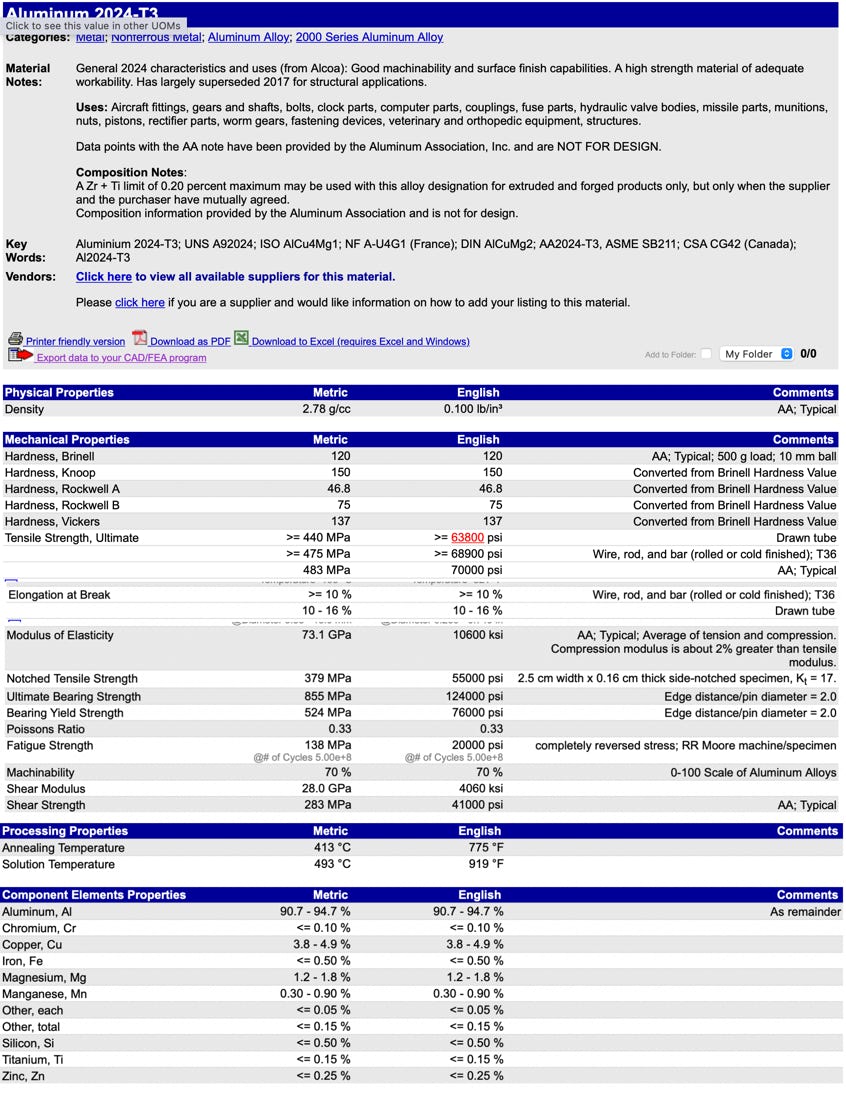

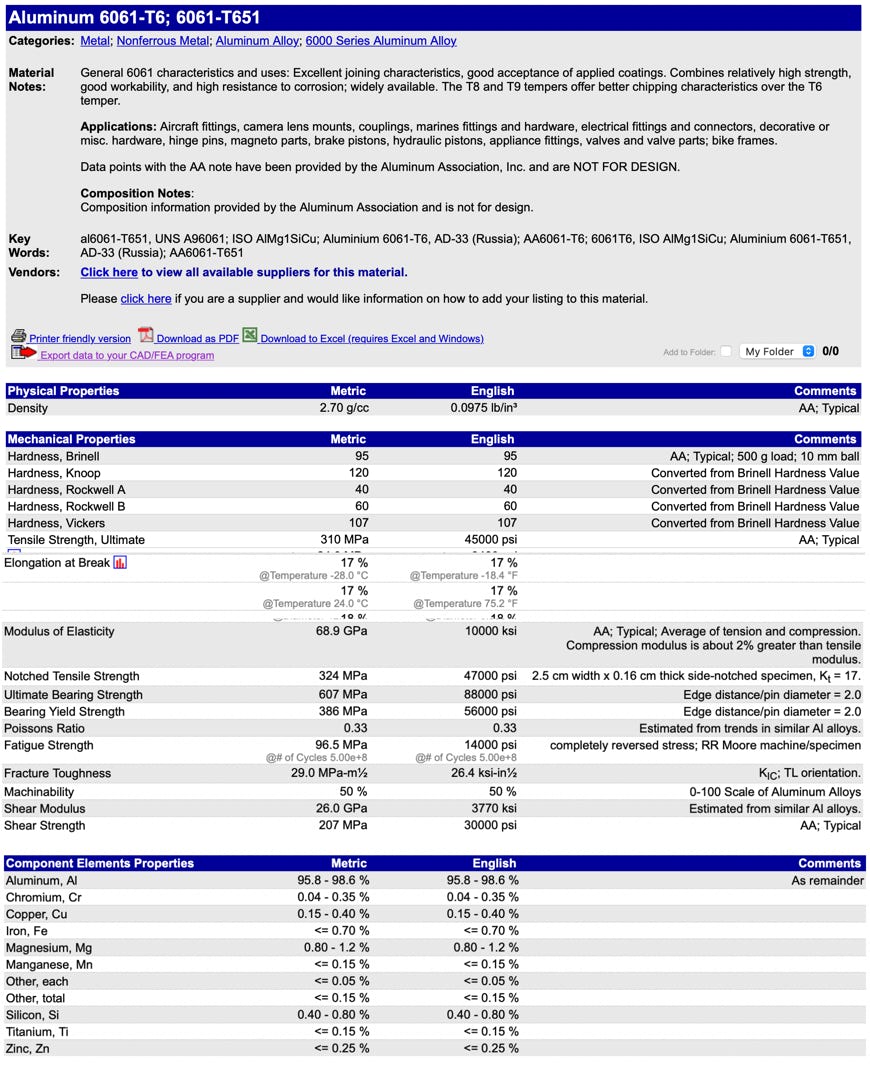

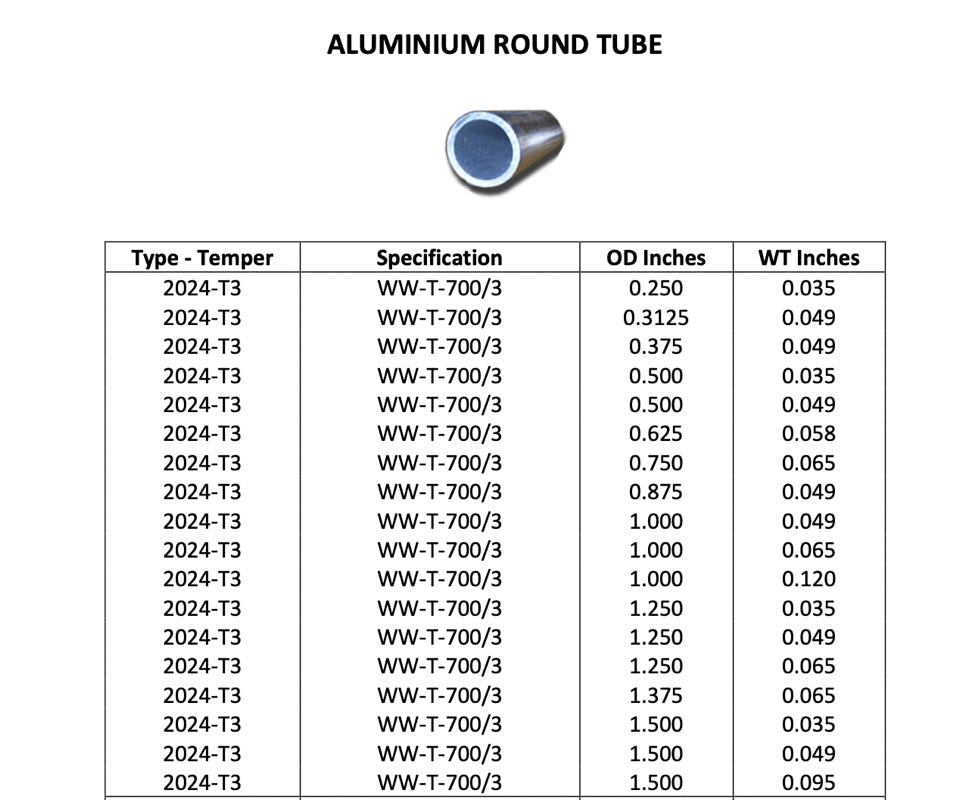

First step is the tube size--what tube available? Material, diameters, wall thicknesses.

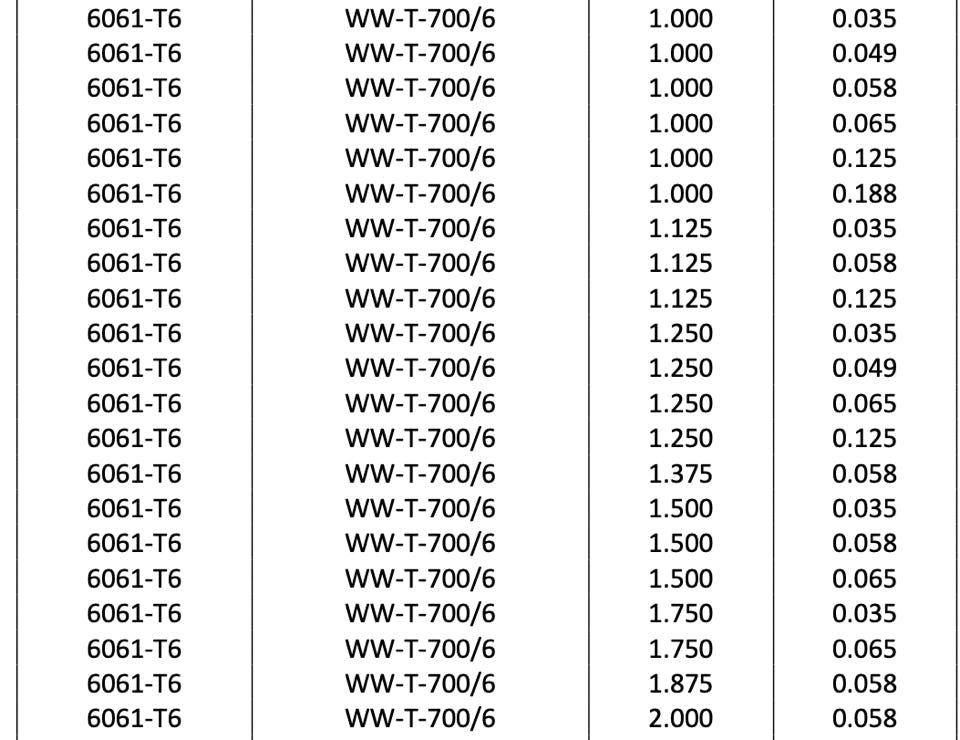

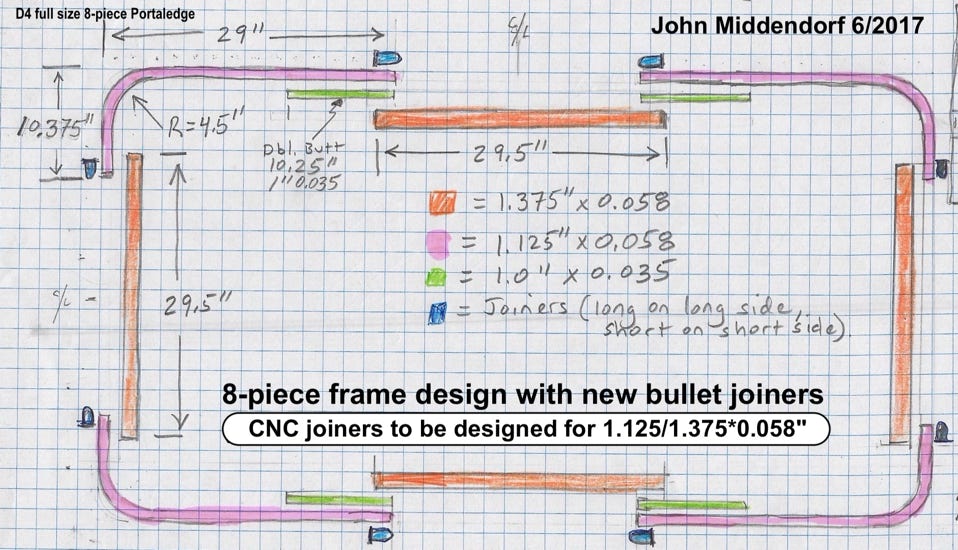

Good tubing for one-person ledge is 1.25"OD, 0.058" wall thickness, and 1" OD, 0.065" wall Aircraft Seamless 6061-T6 tube. Ideal tubing for two-person ledge is 1.375"OD, 0.058"wall, and 1.125"OD, 0.058" wall 6061-T6 tube. In areas of highest stress, you can reinforce the 1.125" OD, 0.058" tube with 1" OD 0.035" wall tube sleeved inside.

IMPERIAL TUBE SOURCES (USA):

USA: https://www.aircraftspruce.com and https://www.wicksaircraft.com

(many larger order suppliers-- Thomas Register listings for "6061-T6 Seamless Tubing" https://www.thomasnet.com )

Imperial Tube Reference/Stocklists: Jorgensen and Tube Sales (reference only)

IMPERIAL TUBE SOURCES (Australia):

The most reliable supplier of tubing in Australia is Airport Metals (Bralco). You can download their stocklist. Unfortunately, they do not stock 1.25” 0.058” 6061-T6 tube. Below is a screenshot of a monthly stocklist for their 2024 and 6061 tube.